Sacramento Roofing Companies Explain Flashing

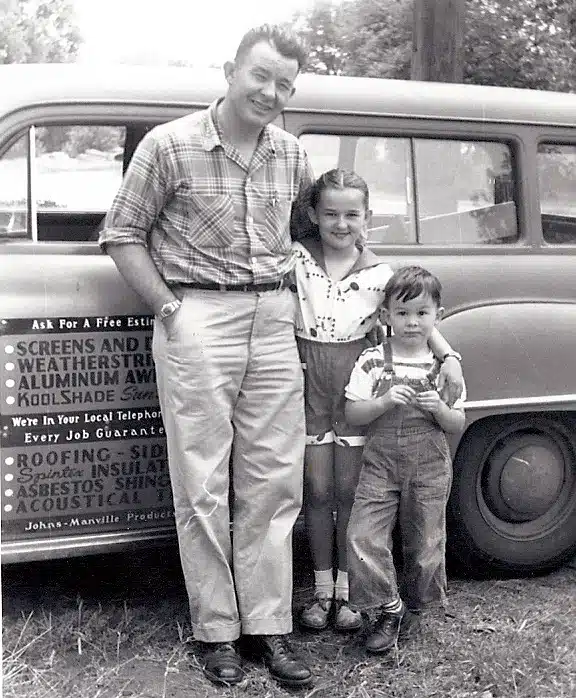

The Yancey Family, Serving Sacramento Since 1888

Flashing is used by your local Sacramento roofing companies to aim the water flow of your roof. Water should flow down and away from the interior of the structure, moving from the top of the roof towards the gutters. The top edge of the flashing directs the flow of water away from the bottom of the underlayment in order to keep it from coming into contact with the wood structural panel sheathing.

The Different Types of Flashing

There are different types of fl ashing, such as vent pipe flashing which fits over pipes or flues or step flashing, that is fit to every course of shingles, protecting the joints between the dormers and roof deck. Where two roof planes join is a particularly vulnerable area and valley flashing is designed to protect that spot. It is installed over the top of the felt before all the finishing material is installed.

ashing, such as vent pipe flashing which fits over pipes or flues or step flashing, that is fit to every course of shingles, protecting the joints between the dormers and roof deck. Where two roof planes join is a particularly vulnerable area and valley flashing is designed to protect that spot. It is installed over the top of the felt before all the finishing material is installed.

There are strips of flashing material called drip edges, that run along with eaves, to divert water from under the finished roof. Flashing is important for blocking leaks in areas where the plane of the roof intersects a ridge, or where another roof intersects at an angle or penetration. There could be many such areas on a basic, simple roof, so flashing needs to be installed correctly, to keep leaks from happening.

Roofing Materials Need to Contract and Expand

Metal flashing is usually soldered, or brazed, which bonds two strips of metal into one piece. If any flashing elements need to wrap around corners, metal flashing could be brazed or soldered to create a dependable joint and protect the roof. The elements can be very rough on roofing materials. Extreme temperatures, snow, ice, and humidity all take their toll. All roofing materials contract and expand as a result of these changes in weather.

Two Pieces Moving in Harmony

Flashing materials have to be leak proof in order to keep the elements from penetrating your roof, causing damage. A two part flashing system can prevent this from happening.

Base flashing can be laced into the roofing materials that are then covered by another metal flashing piece. The second metal piece is not anchored to the base. That lets each piece move independently when the roofing materials get battered by the elements.